FAQs

ALL ZOMODO faucets are made from 100% SUS304 or 316 stainless steel

Q: SO WHAT’S THE DIFFERENCE BETWEEN STAINLESS STEEL AND BRASS FAUCETS?

Health & Safety

- Stainless steel is lead-free → safe for drinking water.

- Brass may contain small amounts of lead, even if labelled “low-lead.”

Durability

- Stainless steel is harder and stronger → lasts longer in busy kitchens.

- Brass is softer and can wear out faster.

Corrosion Resistance

- Stainless steel resists rust and corrosion very well.

- Brass can corrode over time (dezincification).

Hygiene

- Stainless steel is non-porous → easier to clean, bacteria don’t stick.

- Brass can tarnish and hold more grime.

Safety Standards

- Stainless steel often meets stricter safety certifications without coatings.

- Brass usually needs plating (nickel, chrome, etc.), which can wear off.

Sustainability

- Stainless steel is 100% recyclable.

- Brass is recyclable too, but harder to process because of lead content.

Style

- Stainless steel → modern, sleek look.

- Brass → traditional, classic look.

Cost

- Stainless steel faucets cost more upfront, but last longer.

- Brass is cheaper but may not be as safe or durable.

Q: MY ZOMODO SINK SHOWS SCRATCHES SHORTLY AFTER INSTALLATION. WHAT CAN I DO?

- All stainless steel will scratch, especially high-lustre finishes like Cayman, Montego, and Integrato.

- That’s why every Zomodo sink includes a Sink Care Pack (polishing cream, oil, and scouring pads).

- Use this kit to buff out early scratches and keep your sink shiny.

- Over time, scratches blend into a natural finish called a patina. The sink will look slightly softer, but scratches become less noticeable.

- Additional cleaning products can be purchased in our Product Care Section.

Q: WILL MY (PEARLARC) PVD COLOURED SINK SCRATCH? WILL THE COLOUR COME OFF?

- Yes, all stainless steel scratches. PVD sinks are no different.

- Unlike coatings (paint, powder coating, plating), PVD is deposited into the steel at the molecular level.

- Normal light scratching will not penetrate the PVD membrane and just appear as a duller coloured area on the sink.

- Over time, your sink will develop a coloured patina that blends scratches into the finish.

- We recommend to read about the (PearlArc) PVD technology in the PearlArc Collection Section to get a basic understanding of the colouring and protective scratch resistant process.

- Avoid abrasive cleaners, steel wool, or heavy-duty scouring pads. Rubbing the sink aggressively with these items may significantly wear the coloured surface and even penetrate the (coloured) PVD membrane

Q: WHAT IS PVD AND HOW DOES IT COLOUR STAINLESS STEEL?

- PVD (Physical Vapor Deposition) is a vacuum-based coating process that deposits an ultra-thin, extremely durable metal-compound layer onto stainless steel.

- The color comes from the coating itself, not paint or dye—and it becomes part of the surface.

Step-by-step: how stainless steel gets its PVD color

- Surface preparation (critical step). The stainless steel part is: Polished / brushed to final finish, Ultrasonically cleaned, Degreased and dried. *Any defect here shows through the coating—PVD does not hide flaws.

- Vacuum chamber loading: Parts are placed inside a sealed vacuum chamber, and air is removed to create an ultra-low-pressure environment.

- Why?

- Prevents contamination

- Allows atoms to travel freely and bond cleanly

- Metal target vaporization: A solid metal target (commonly titanium, zirconium, or chromium) is energized using:

- Electric arc (Arc PVD)

- Magnetron sputtering (Sputter PVD)

- This turns the solid metal into a metal vapor (plasma).

- Reactive gas = color creation. Reactive gases are introduced:

- Nitrogen (N₂) → gold, bronze, champagne

- Carbon (C₂H₂ / CH₄) → black, graphite

- Oxygen (O₂) → blue, rainbow, oxide tones

- The metal vapor reacts with these gases to form metal nitrides / carbides / oxides, which determine: Color, Hardness, Chemical resistance

- Atomic bonding to stainless steel. The vaporized particles:

- Accelerate through the plasma

- Bond at the atomic level to the stainless steel

- Build up a coating only 1–5 microns thick

- This is why PVD: Doesn’t peel, Doesn’t flake, Keeps sharp edges crisp.

Q: WHY IS (PEARLARC) PVD IDEAL FOR FAUCETS, SINKS AND HARDWARE?

- Durability advantages

- Hardness: ~2000–3000 HV (vs ~200 HV for chrome)

- Scratch resistance: dramatically higher

- Corrosion resistance: excellent (salt, cleaners, humidity)

- UV stability: won’t fade or yellow

- Aesthetic advantages

- Metallic depth (not flat like paint)

- Consistent tone across batches

- Can be satin, brushed, or mirror

- What PVD is not

❌ Not paint

❌ Not electroplating

❌ Not anodizing (that’s for aluminum)

Q: I ORDERED A ZOMODO PRODUCT AND IT HASN’T ARRIVED. WHAT SHOULD I DO?

- Please contact the retailer or wholesaler where you placed your order.

- If the product is on back order, they should be able to give you an estimated delivery date.

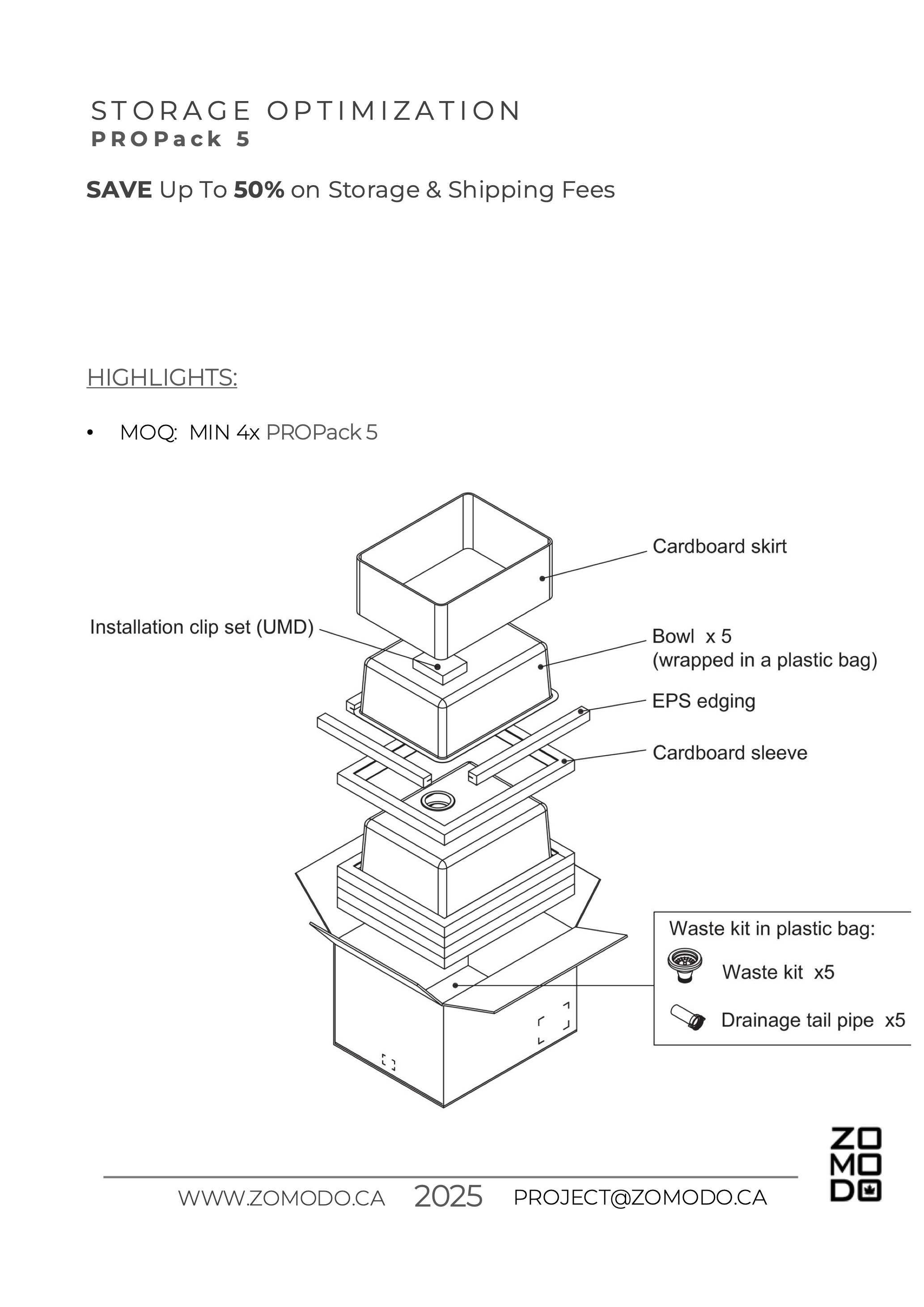

Q: WHAT IS A PROPACK 5 OR 5-PACK IN THE ZOMODO PROJECT SINK PROGRAM?

- The PROPack 5 (or 5-Pack) consists of 5 individually wrapped sinks stacked in lots of 5 in a reinforced Master Box.

- The PROPack 5 is ideal for small job sites of 5-20 units and keeps the sinks well protected and easy to transport.